Size Chart

Home / Size Chart

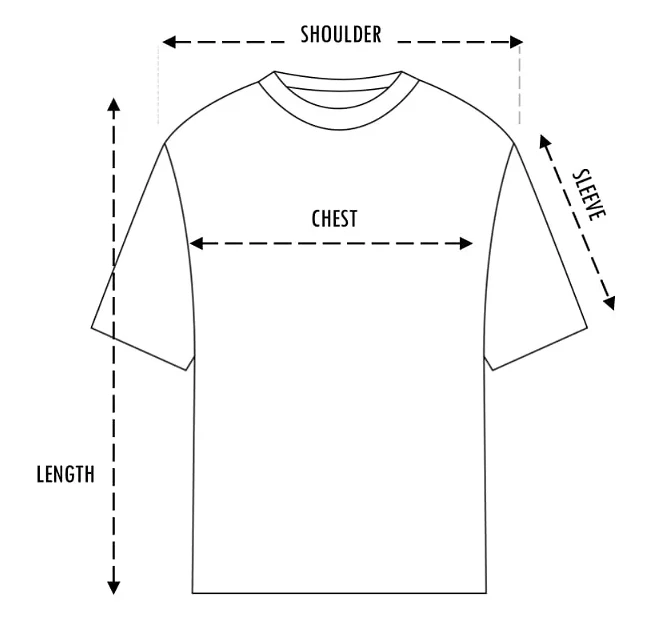

Mens T-Shirt & Polo Size Chart

Dear Valued Customer, We understand the importance of finding the perfect fit when it comes to your T-shirts and Polo shirts. To assist you in making the right choice, we have provided a comprehensive size chart below. Please refer to the measurements to ensure that your new garment fits comfortably and suits your style.

| Sizes (EU) Inches | XS | S | M | L | XL | XXL | 3XL |

|---|---|---|---|---|---|---|---|

| Shoulder | 16.5 | 17 | 17.5 | 18 | 19 | 20 | 21 |

| Chest | 38 | 40 | 41 | 42 | 43 | 44 | 45 |

| Arm Hole | 17 | 18 | 19 | 20 | 21 | 22 | 23 |

| Length | 27 | 28 | 29 | 30 | 31 | 32 | 33 |

| Sleeve Length | 8 | 8.5 | 9 | 9.5 | 10 | 10.5 | 11 |

Women T-Shirt & Polo Size Chart

| Women (Asian) | Women (European) | Chest | Length | Sleeves Length |

|---|---|---|---|---|

| S | XS | 17.5 | 24.5 | 6.5 |

| M | S | 18.5 | 25.5 | 7 |

| L | M | 19.5 | 26.5 | 7.5 |

| XL | L | 20.5 | 27.5 | 8 |

| 2XL | XL | 21.5 | 28.5 | 8.5 |

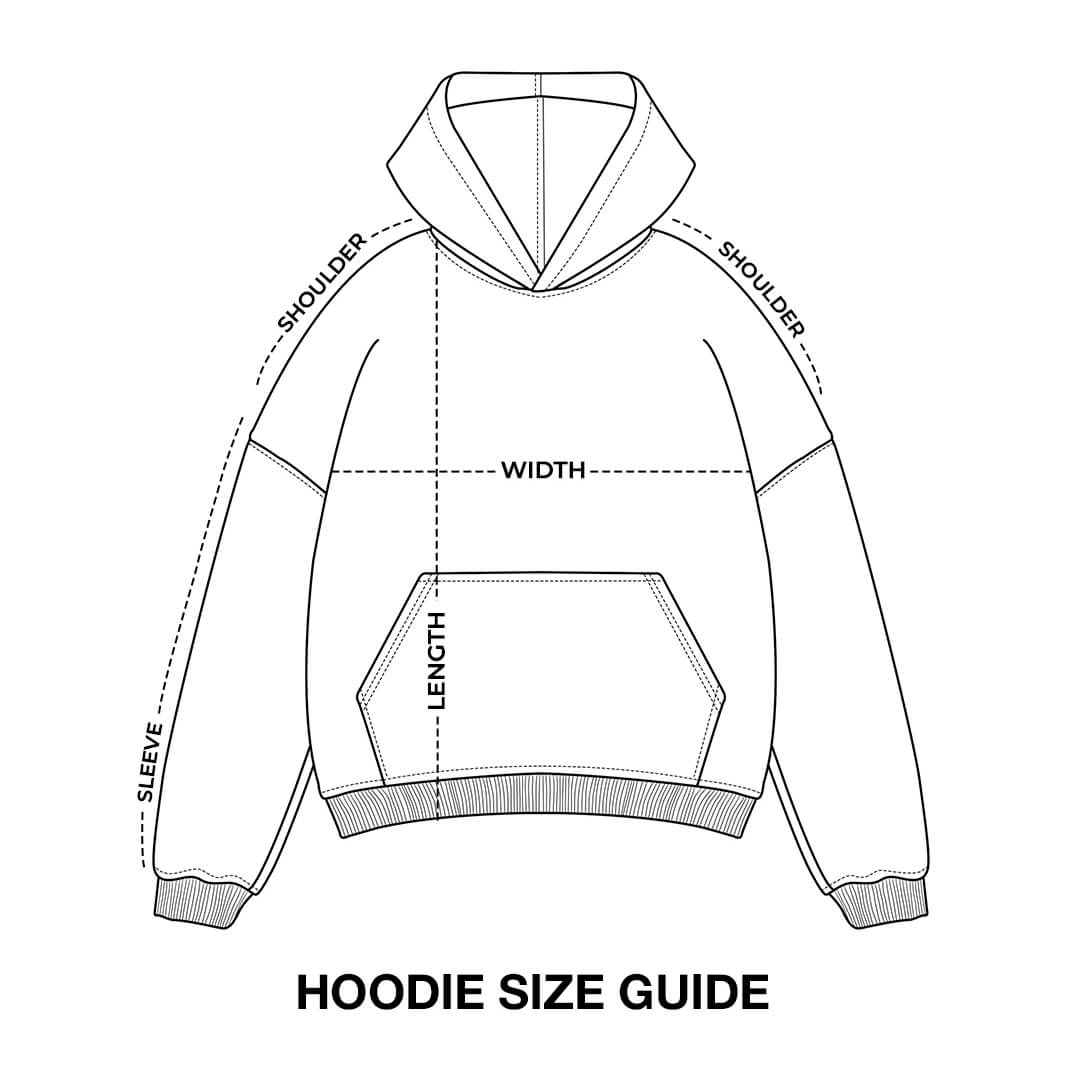

Unisex Hoodie Size Chart

| Unisex Adults | Chest | Length | Shoulder | Sleeves Length |

|---|---|---|---|---|

| S | 20 | 26 | 17 | 24 |

| M | 21 | 27 | 18 | 24.5 |

| L | 22 | 28 | 19 | 25 |

| XL | 23 | 29 | 20 | 25 |

| 2XL | 24 | 30 | 21 | 25.5 |

Oversize T-Shirt Size Chart

| Sizes Inches | XS | S | M | L | XL | XXL |

|---|---|---|---|---|---|---|

| Shoulder | 19 | 20 | 21 | 22 | 23 | 24 |

| Chest | 42 | 44 | 46 | 48 | 50 | 52 |

| Length | 29 | 29.5 | 30 | 30.5 | 31 | 31.5 |

| Sleeve Length | 10.5 | 11 | 11.5 | 12 | 12.5 | 13 |

| Arm Hole | 19 | 20 | 21 | 22 | 23 | 24 |